In times where flying hours are up one year, down the next and contractual rates increasingly competitive it’s all the more important to optimize DMC (Direct Maintenance Cost). As you know, the highest maintenance cost on a helicopter is the power unit consisting of the engines and combining gearbox. This is why it’s all the more important to get it right when it comes to global understanding of options and key considerations.

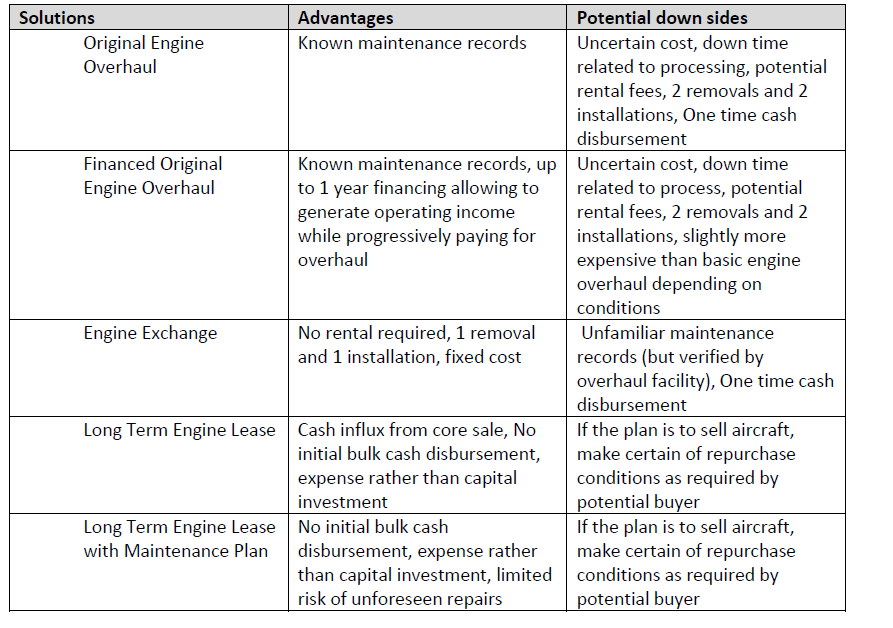

In this article I will share my experience in managing engine overhauls and how best to minimize cost while getting your helicopter engine ready in time. You have several options to consider when making your decision on refurbishment of your aircraft engines. Different options bring advantages and potential downside. Here is a comparative table to help assess what is best in your situation:

5 Solutions to get an Engine in Overhauled Condition

As a first step I would recommend making a decision on the above solution depending on your cash flow situation, cost tolerance, planned aircraft possession timeline and other potential considerations.

What is the actual cost of an helicopter engine overhaul ?

Now let’s examine what an helicopter engine overhaul “should cost”. The first consideration is understanding what the market is for the power unit on an outright purchase basis. This will then help determine what is reasonable to pay for repairing or overhauling a unit.

From our experience and our own current pricing practices, freshly overhauled PT6T-3B engines with good pedigree and rotating components that will last full TBO (time between overhaul) of 4000 hours with at least 2 cycles per hour will be priced from 345,000$ to 375,000$. Obviously this will depend on supply and demand and customer preferences. From the outright price you then deduct the core engine value.

Again depending on life remaining on rotating components, configuration, and time since new the core will be worth between 40,000$ and 75,000$ for a PT6T-3B engine. Therefore basic math applied the max you will want to pay for overhaul is (345,000 min outright price – 75,000 max core value) = 270,000$ and (375,000 max price – 40,000 min core value) = 335,000$. So now we have our target: 270,000$ – 335,000$ including accessories.

As a rule of thumb, if you get a cost estimate or expect your helicopter engine to be over 300,000$, I would strongly recommend you hit the market. This will allow you to see what options you have depending on your specific requirements and to ask suppliers what value you will get for your core on an exchange basis.

When shopping the market, keep in mind the conditions required will define supply. For example some customers will require dual certification FAA & EASA or certification by other civil authorities. Others will expect low time since new. Also depending on mission profile (high cycle usage vs low cycle usage) different rotating part lives can be required to optimize DMC.

3 Tested and True Tips to Reduce Cost:

1. Plan ahead: More you have time ahead of you more you can…

a) Get firm quotes from suppliers or qualitative conditions (new helicopter parts discount, labour cost, customer supplied part embodiment rates)

b) See what exchange options are available

c) Have a partner build up engine based on your specific needs. For example, if your mission profile allows for it installing a lower cycle remaining CT disk may save you 30-50,000$ on your exchange.

2. Evaluate installing FAA & TCCA approved PMA (Parts Manufacturer Approval) or DER (Design Engineering Representative) repaired parts.

3. Make use of serviceable overhauled components to for parts needing replacement

a) Leverage partners such as Optima Aero with large helicopter parts inventories to supply aircraft parts discounted from 50% to 70% vs new parts

b) Encourage your overhaul shop to search the market or help them by providing sources yourself for helicopter and engine parts

By applying these methods, Optima Aero has been able to supply engine overhauls consistently under 240,000$. I encourage you to reach out to us at Optima Aero for explanations on the above information or to inquire about other engine models. We have solutions designed and tested that will help you optimize DMC, cash flow and asset availability.

Maintain well, fly well, Operate best,

Toby,

President, Optima Aero inc.